Maximizing Efficiency with High Output Case Erector Jigs

In the ever-evolving landscape of modern manufacturing and packaging, businesses are continually seeking methods to optimize their production processes. One area that has seen significant advancements is the automation of packaging lines. A critical component in this realm is the high output case erector jig, a specialized device that streamlines the formation and sealing of boxes, allowing companies to scale their operations effectively. This article will explore the importance, functionality, and benefits of high output case erector jigs, alongside valuable insights into the world of 3D printing and accessories related to these innovations.

The Role of Case Erector Jigs in Modern Packaging

Case erector jigs are machines designed to automatically form and erect cases from flat sheets of cardboard. This process is pivotal in industries where packaging speed and efficiency are paramount, such as food and beverage, pharmaceuticals, and consumer goods. By utilizing a high output case erector jig, companies can not only reduce the labor required for manual assembly but also enhance packaging quality and consistency.

Understanding How High Output Case Erector Jigs Function

The design of a high output case erector jig enables rapid production while maintaining precise standards. Here’s a breakdown of how they work:

- Automated Feeding: Sheets of cardboard are automatically fed into the machine.

- Forming Mechanism: The jig quickly folds and shapes the cardboard into a three-dimensional box.

- Sealing Process: Once the case is formed, it is sealed with adhesive or tape.

- Output Capacity: High output machines can produce hundreds of boxes per hour, significantly improving throughput.

Benefits of Implementing High Output Case Erector Jigs

Investing in a high output case erector jig offers numerous advantages that contribute to the overall productivity and efficiency of a business. Here are some of the key benefits:

- Increased Production Speed: Automating the case erecting process reduces cycle times, allowing for faster packaging.

- Labor Cost Reduction: Fewer workers are needed to operate the packaging line, mitigating labor costs.

- Enhanced Quality Control: Automated systems minimize human error, ensuring that every box is consistently well-formed and sealed.

- Space Efficiency: Modern jigs are designed to take up minimal floor space while maximizing output. Many models are compact and can fit into existing production lines without extensive modifications.

- Versatility: High output case erector jigs can handle various box sizes and styles, making them adaptable for different product lines.

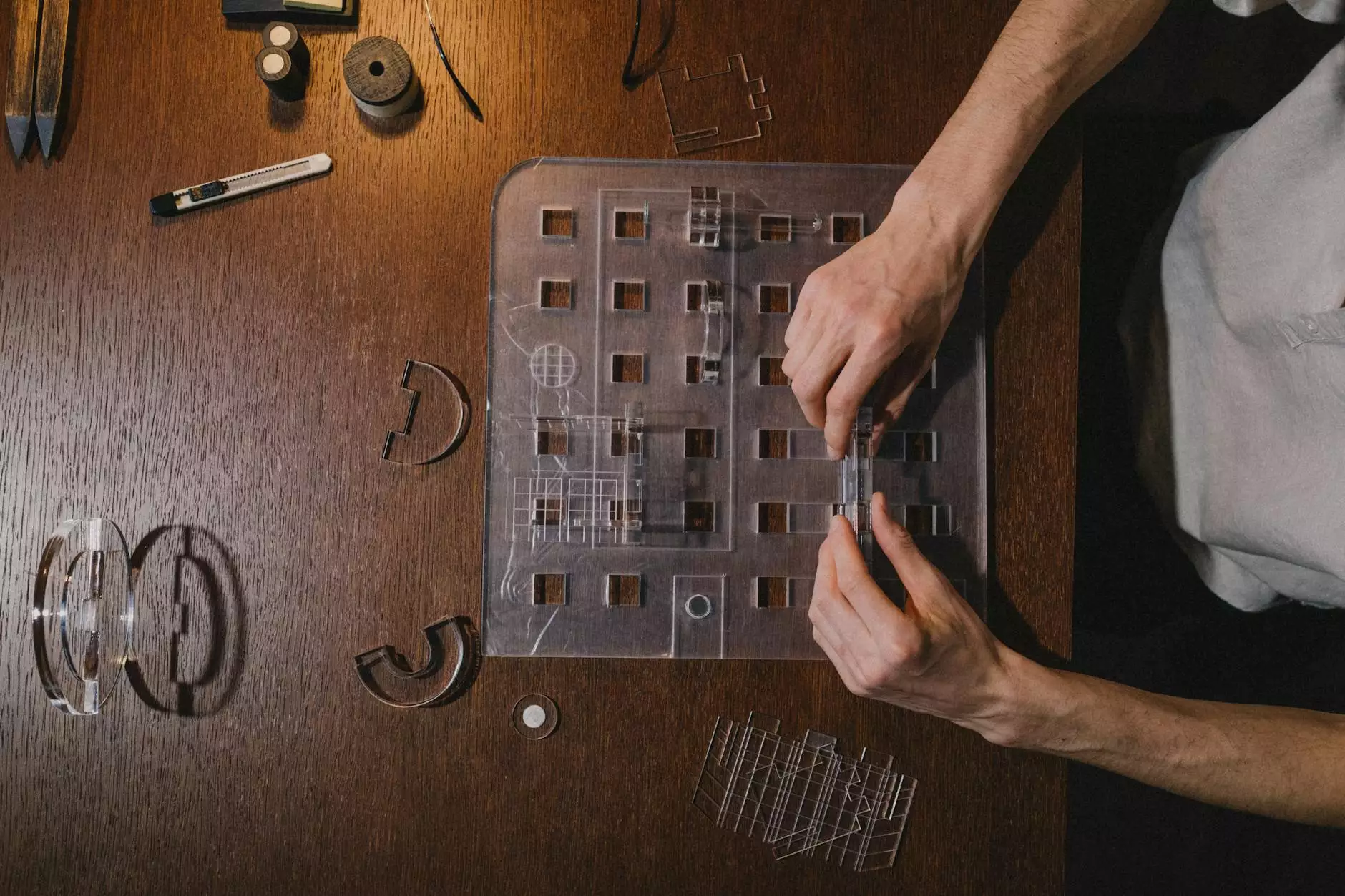

Integrating 3D Printing into Packaging Solutions

One of the most exciting advancements in packaging technology is the integration of 3D printing. This innovative approach allows manufacturers to create custom packaging solutions tailored to specific product needs. Here are some compelling advantages of utilizing 3D printing alongside high output case erector jigs:

Customization at Scale

3D printing offers unprecedented levels of customization. Businesses can design unique packaging shapes or sizes that traditional methods cannot easily achieve. By pairing this customization with a high output case erector jig, companies can maintain high production rates while offering personalized packaging solutions.

Rapid Prototyping

Before committing to a large production run, businesses can use 3D printing to create prototypes of their packaging designs. This capability allows companies to test different designs and materials without losing precious time or resources.

Reduced Material Wastage

3D printing allows for more efficient material usage, minimizing waste during the packaging development process. Combined with a high output case erector jig, organizations can optimize their overall material consumption in the packaging phase.

Accessories and Enhancements for High Output Case Erector Jigs

To further maximize the efficiency of high output case erector jigs, several accessories can be integrated into the system. Here are some notable accessories that can streamline operations:

- Sensor Systems: Advanced sensors can be installed to monitor production speeds, detect jams, and ensure optimal operation.

- Customizable Conveyor Systems: Connecting conveyor systems can enhance the flow of products from the case erector to the filling and sealing stages.

- Software Integration: Advanced software solutions allow for real-time monitoring and management of production metrics.

- Maintenance Tools: Periodic maintenance accessories help ensure the longevity and reliability of the equipment.

The Future of Packaging Automation

As businesses increasingly move toward automation, the future of high output case erector jigs looks promising. Here are some trends likely to shape the industry in the coming years:

Smart Technology Integration

With the rise of the Internet of Things (IoT), manufacturers will begin to integrate smart technology into their case erecting machines. Smart sensors and data analytics will allow for predictive maintenance, reducing downtime and improving production efficiency.

Sustainable Packaging Solutions

As environmental concerns grow, businesses will prioritize sustainable packaging methods. High output case erector jigs will evolve, incorporating eco-friendly materials and practices.

Enhanced Collaboration with 3D Printing

The collaboration between high output case erector jigs and 3D printing technology will expand, allowing for even more personalized and unique packaging solutions.

Conclusion

In conclusion, adopting a high output case erector jig is a strategic move for businesses looking to enhance their production processes. Coupled with the benefits of 3D printing and essential accessories, companies can realize significant improvements in efficiency and quality control. The ongoing evolution of packaging technology signifies a future where businesses can thrive in competitive markets, ready to meet the challenges and demands of modern consumers. Investing in these advanced systems is not just about optimizing current operations but also about being at the forefront of innovation and sustainability in the packaging industry.

To learn more about enhancing your packaging processes with high output case erector jigs and explore accessories for your 3D printing needs, visit shinebenmach.com today!